Full Machining Capabilities to Produce Desired End Products

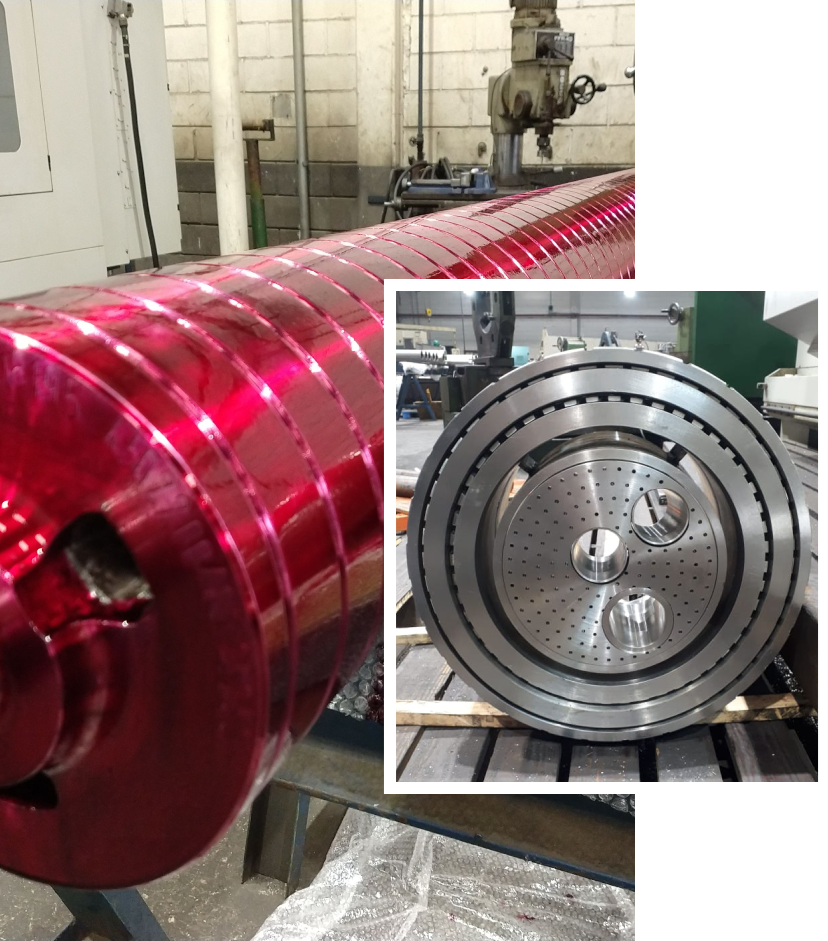

Turning

Turning or lathing rotates the workpiece onto a machine, while a single-edge tool is stationary. In this process, the cutting tool is operated slowly parallel to the rotating axis of the workpiece to remove the material as it passes.

Drilling

Drilling creates a circular hole by spinning a cylindrical tool parallel to the workpiece’s axis of rotation. The hole is the same in diameter as the tool used.

Milling

Milling removes material with the help of rotary cutters from a workpiece in a movement perpendicular to the rotational axis of the cutting tool.

How does Machining Work?

Machining is usually done with a CNC machine, which stands for Computer Numeric Control. Essentially, computer software is used to take CAD design and map tool paths and transform designs into 3D manufactured components. The CNC can build components from a variety of solid materials with the closest accuracy.001”.

In contrast to rapid prototyping, parts are machined with materials that represent the completed design's density, finish, and porosity. Machined components may be utilized for representative tests, models comprising sliding components with a factor of friction, and sealed components needing 0 rings and gasket surfaces.

![CAP_Recycling_Logo-01[4][3] CAP_Recycling_Logo-01[4][3]](https://castalloyproducts.com/wp-content/uploads/2022/08/CAP_Recycling_Logo-0143.jpg)